3D printing has revolutionized manufacturing, allowing creators to turn digital designs into physical objects with ease. However, the cost of 3D printing can add up quickly, especially for complex or high-volume projects. Fortunately, strategic design choices can significantly reduce these costs. Here are some tips from our printing team on how to save on 3D printing expenses by optimizing your designs.

1. Optimize Your Design for Material Usage

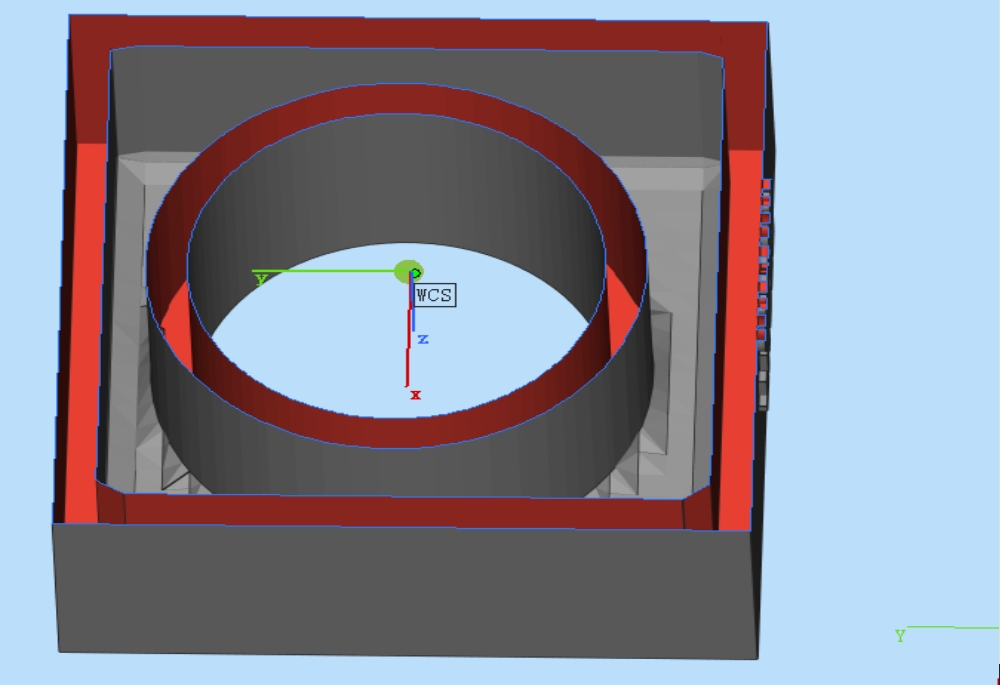

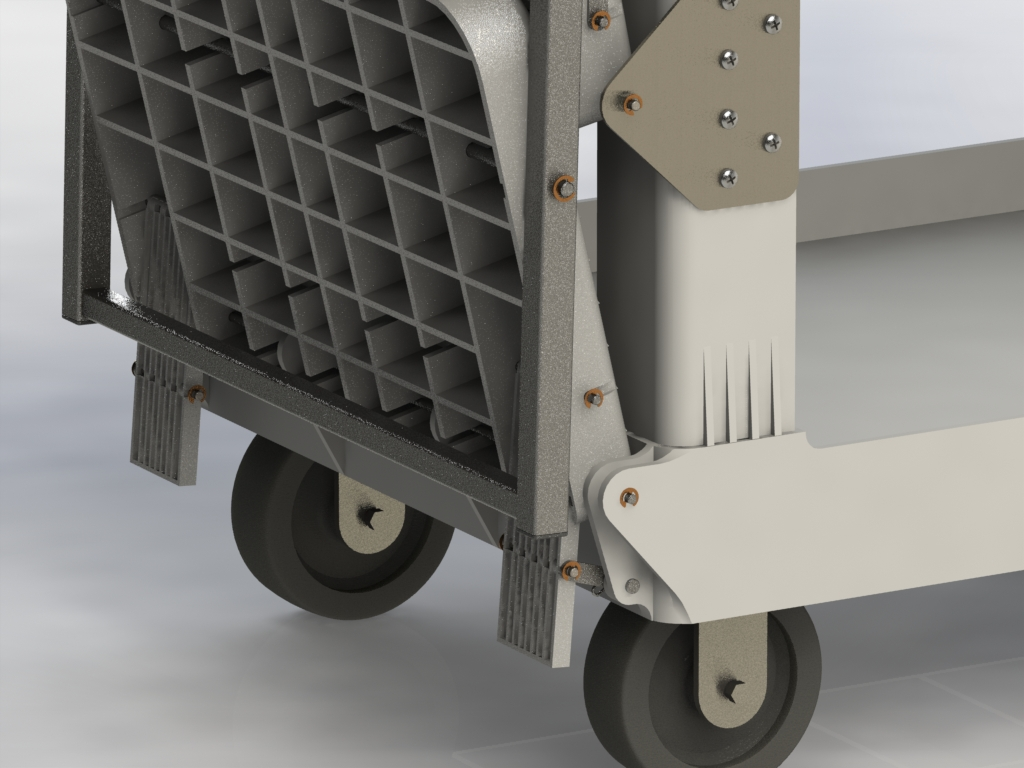

. Hollow Out Your Models

– Why: Reducing the amount of material used can drastically cut costs.

– How: Use software tools to hollow out solid parts, leaving enough wall thickness to maintain structural integrity.

– Recommended wall thickness: SLA resins for 2.5mm minimum, SLS nylons between 2mm to 5mm, SLM metals for 1.2mm minimum, FDM Plastics 1.2mm minimum.

. Use Infill Wisely-Ideal for FDM 3D Printing only

– Why: The density of the infill impacts both material use and print time.

– How: Choose a lower infill density for non-structural parts. A 20-30% infill is often sufficient for most applications, striking a balance between strength and material savings.

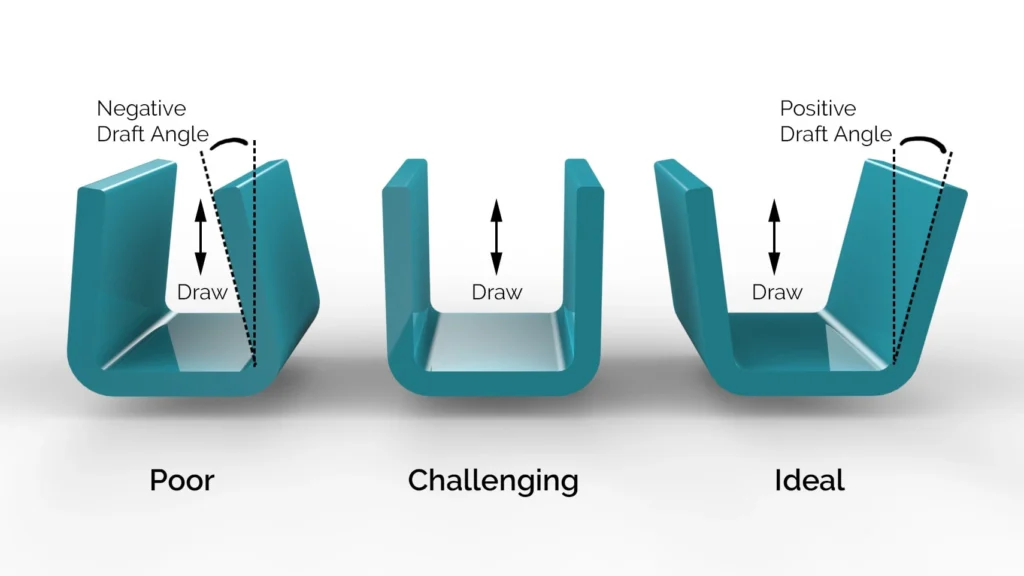

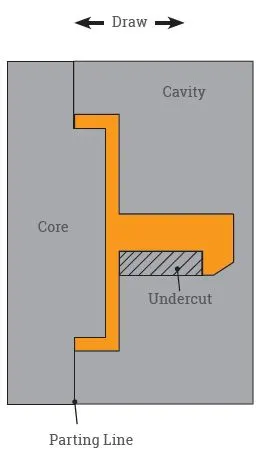

2. Minimize Supports and Overhangs

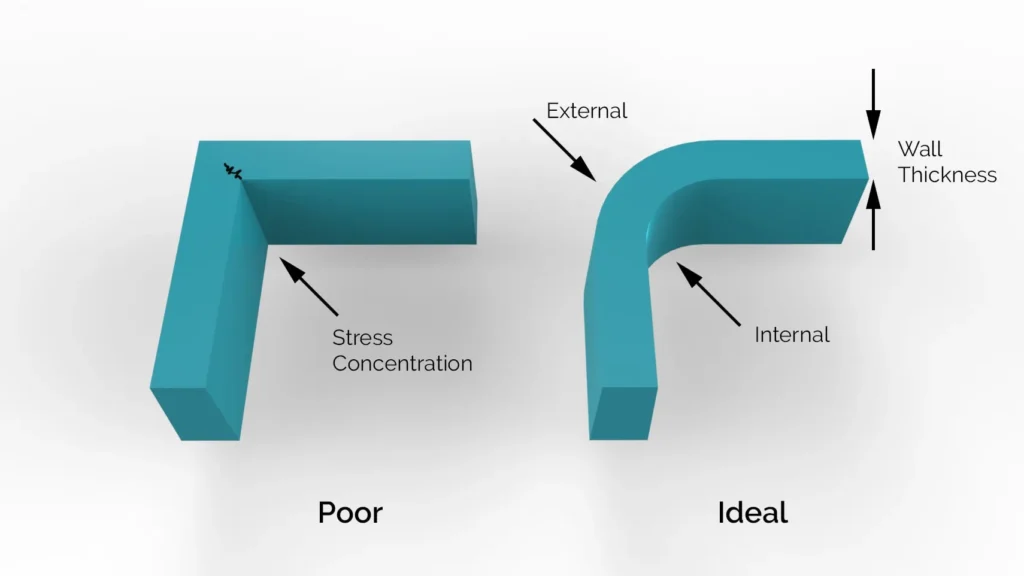

. Design with Self-Supporting Angles

– Why: Supports add to material costs and require additional post-processing.

– How: Design parts with overhang angles greater than 45 degrees to minimize the need for supports. Integrate features like chamfers or fillets to support overhangs.

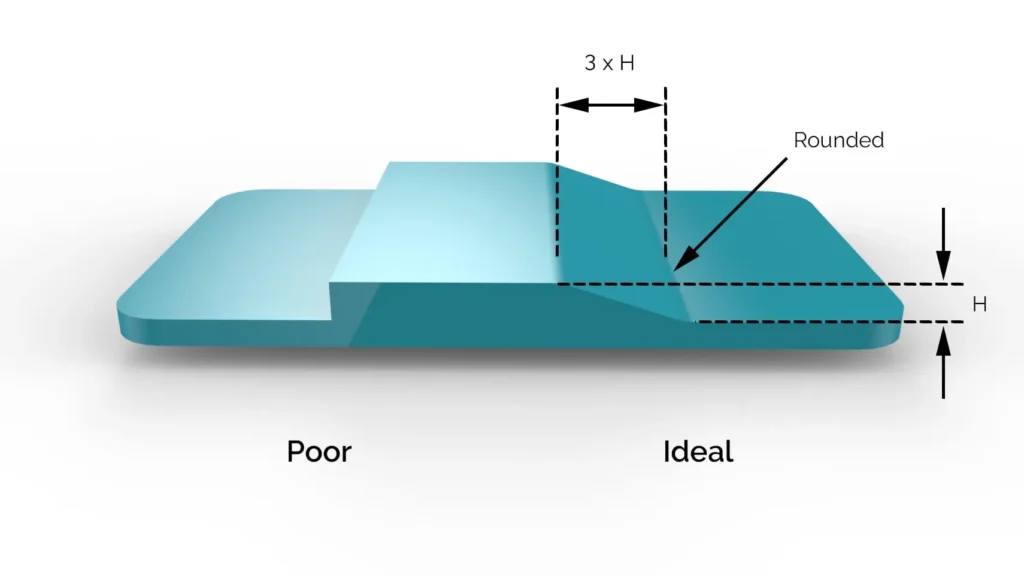

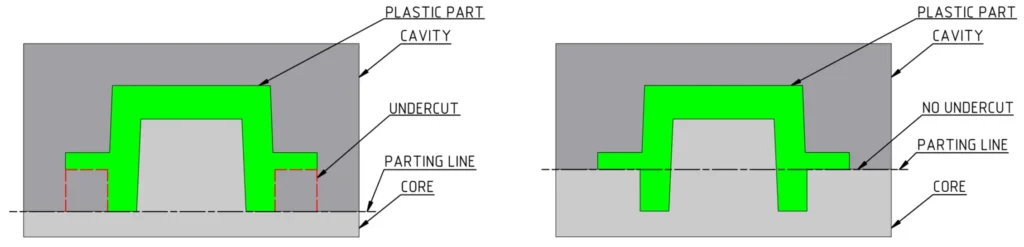

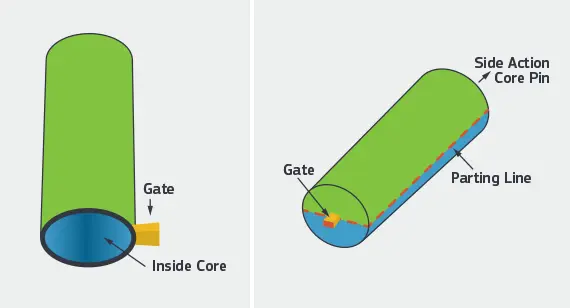

. Split Complex Models

– Why: Large, intricate parts may require a lot of supports.

– How: Break down complex models into simpler parts that can be printed without supports and then assembled post-printing.

3. Choose the Right Material

. Consider Cost-Effective Filaments

– Why: Different materials vary greatly in cost.

– How: For prototyping and non-functional parts, opt for cheaper materials like PLA instead of more expensive options like ABS or PETG. Get instant 3D Printing quote in different materials from this link.

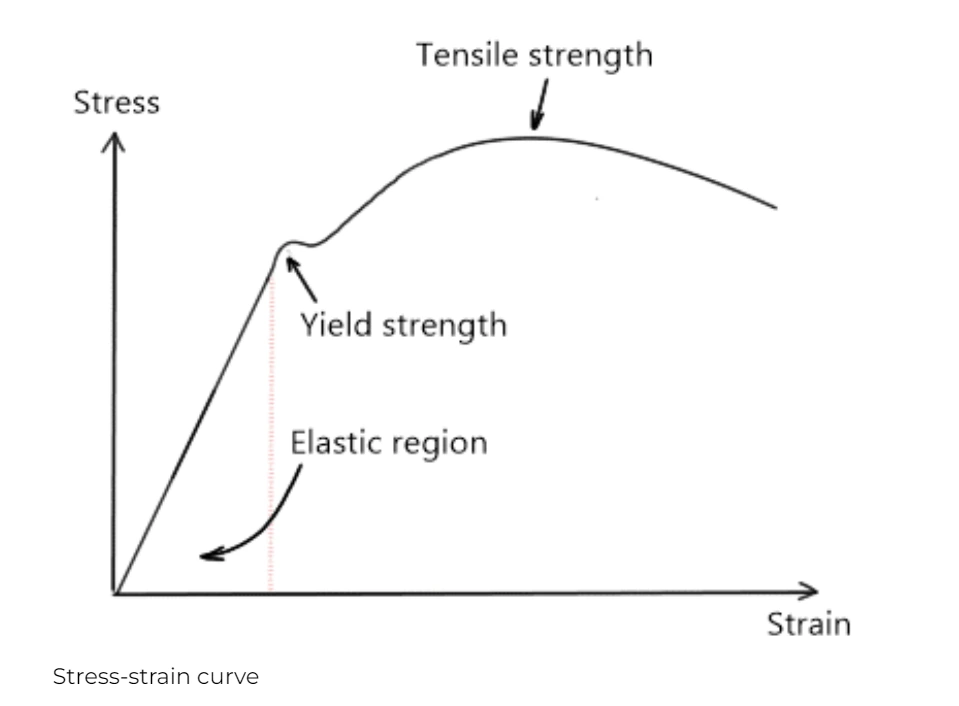

. Leverage Material Properties

– Why: Some materials offer better properties that might reduce the need for additional design features.

– How:Use flexible materials for parts that require bending, or durable materials for high-stress components to avoid over-engineering your design.

4. Optimize Print Settings

. Layer Height Adjustments

– Why: Thicker layers mean fewer layers to print, saving time and material.

– How: Increase the layer height for parts where fine detail is not critical. For example, use a 0.2mm layer height instead of 0.1mm.

-Example: In MJF printing, there are two different options, the fast mode and balanced printing mode. The last one results in high quality parts with much better smoothness. In FDM printing, the biggest nozzle diameter is 1.0mm, which means that it can print same parts with shortest time.

. Print Speed and Temperature

-Why: Optimized print speeds and temperatures can reduce time and material waste.

– How: Calibrate your printer settings to ensure efficient material use without compromising print quality.

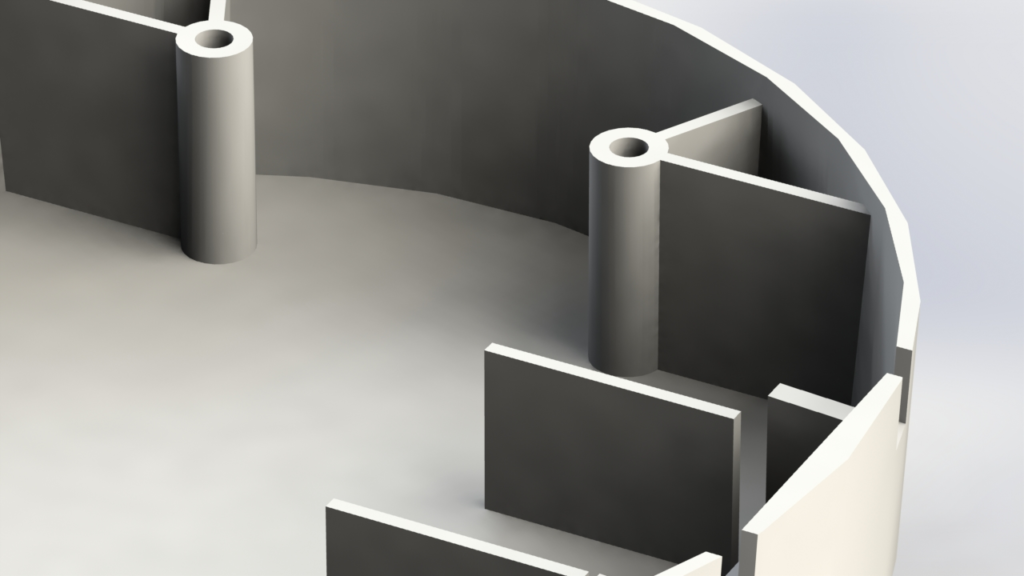

5. Design for Assembly

. Modular Design

– Why:Smaller parts can be printed faster and with less material.

– How: Design your model in modular components that can be easily assembled post-printing.

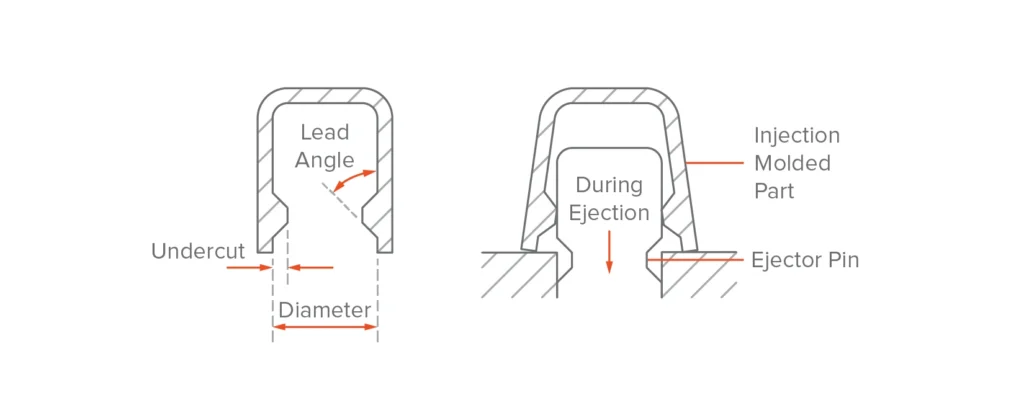

. Use Fasteners and Snap Fits

– Why: Reducing the need for large, solid components cuts down on material usage.

– How:Incorporate features like snap fits or design your parts to be joined using fasteners rather than printing large, monolithic pieces.

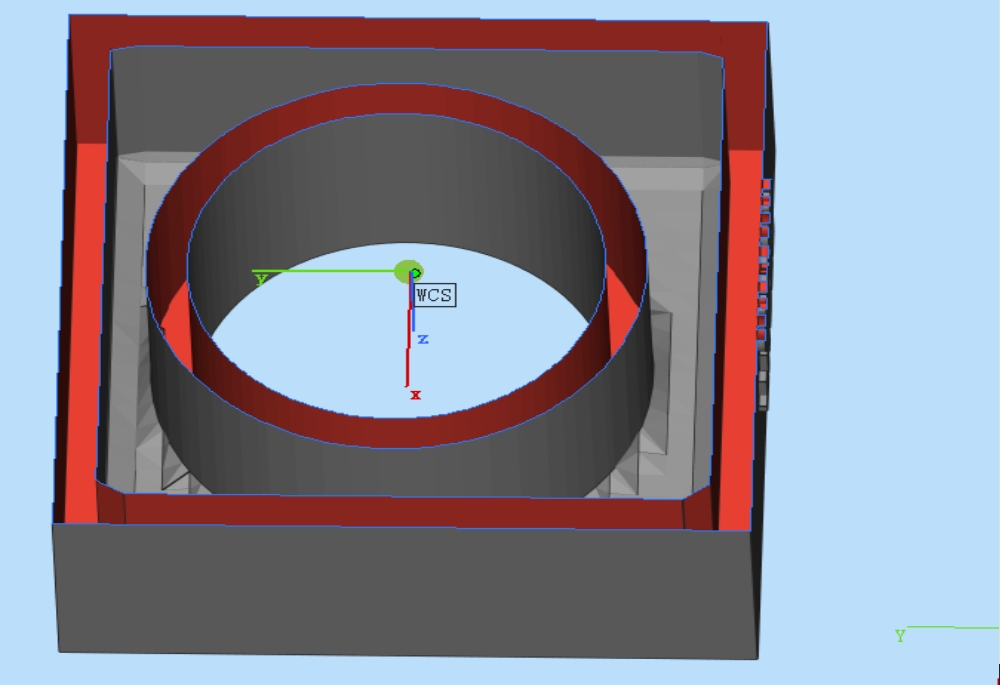

6. Leverage Advanced Software Tools

. Utilize Slicing Software Features

– Why: Modern slicing software offers numerous settings to optimize prints.

– How: Explore options such as variable layer height, adaptive infill, and support structure optimization to reduce material use and print time. Tree support is recommended for most of the parts.

-Recommended software: Let’s say FDM 3D Printing, using software such as Prusa Slicer, Cura, Simplify3d, Bambu studio, OrcaSlicer

. Use Simulation and Analysis Tools

– Why: Understanding how your design performs under stress can prevent over-designing.

– How: Use simulation tools to analyze the load-bearing capacity of your design and adjust accordingly to use less material without sacrificing strength.

Conclusion

By making informed design choices, you can significantly reduce the cost of 3D printing. Focus on material efficiency, minimize the need for supports, choose the right materials, optimize your print settings, design for assembly, and leverage advanced software tools. These strategies not only help in saving costs but also contribute to faster production times and better overall print quality. Happy printing!

Feel free to reach out [email protected]if you have any questions or need further assistance with your 3D printing projects.